How Do Sealed Lead-Acid Batteries Work? The Complete Science Behind SLA Technology

How Do Sealed Lead-Acid Batteries Work? The Complete Science Behind SLA Technology

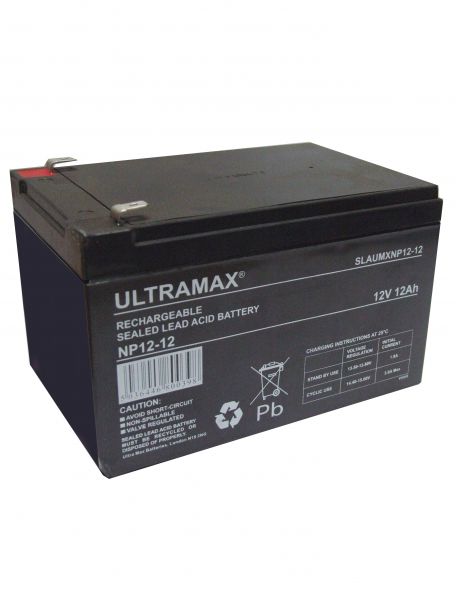

Sealed Lead-Acid batteries are a staple of our modern world, powering everything from emergency backup systems to electric vehicles. But have you ever wondered how they actually work? In this article, we will delve into the inner workings of these powerful energy storage devices, uncovering the secrets behind their reliable performance. Unlike their non-sealed counterparts, Sealed Lead-Acid (SLA) batteries are designed to be maintenance-free and operate in any position. The key to their functionality lies in their construction. Inside the battery, lead plates are immersed in an electrolyte solution made of sulfuric acid and water. When a load is connected to the battery, a chemical reaction occurs between the lead plates and the electrolyte, generating electrical energy. What makes SLA batteries unique is their ability to be recharged, thanks to a process called the lead-acid cell reaction. As the battery discharges, the lead plates transform into lead sulfate and the electrolyte becomes depleted. But when connected to a charging source, such as an electrical outlet, the reaction reverses, converting the lead sulfate back into lead plates and replenishing the electrolyte solution.

Structure and Components of Sealed Lead-Acid Batteries

At the heart of every SLA battery lies a sophisticated arrangement of components working in harmony. The primary elements include positive plates made of lead dioxide, negative plates of pure lead, and a specially formulated electrolyte solution. Think of these components as actors in a carefully choreographed dance of electrons.

The battery case itself is made from durable materials designed to prevent leakage and withstand pressure changes during charging and discharging. Inside, separators made of microporous material keep the positive and negative plates apart while allowing ions to flow freely. This internal architecture ensures efficient energy conversion while maintaining safety.

The most distinctive feature of SLA batteries is their sealed design with a pressure-regulated valve system. This ingenious mechanism allows excess gases to recombine back into water within the battery, creating a closed system that never needs electrolyte replenishment.

Working Principle of Sealed Lead-Acid Batteries

Understanding how SLA batteries work requires exploring the fundamental electrochemical reactions taking place inside. When we connect a load to the battery, it triggers a series of chemical transformations that convert stored chemical energy into electrical energy.

During this process, the sulfuric acid electrolyte reacts with the lead dioxide at the positive plate and pure lead at the negative plate. This reaction produces lead sulfate, water, and, most importantly, free electrons that flow through the external circuit to power our devices.

The beauty of this system lies in its reversibility. Unlike a typical chemical reaction that simply runs to completion, the lead-acid reaction can be reversed with the application of electrical energy, allowing us to recharge the battery multiple times.

Charging Process of Sealed Lead-Acid Batteries

The charging process of SLA batteries follows three distinct stages, each playing a crucial role in maintaining battery health and efficiency. During the bulk charge stage, the battery accepts high current as it recovers most of its capacity. Think of this as filling a glass with water—initially, you can pour quickly without worry of overflow.

As the battery approaches full charge, it enters the absorption stage. Here, the charging current gradually decreases while voltage remains constant. This stage ensures complete conversion of lead sulfate back to lead and lead dioxide, much like slowing down when filling the last bit of the glass to avoid spilling.

Finally, the float stage maintains the battery at full charge while preventing overcharging. This stage compensates for self-discharge, keeping the battery ready for use while protecting its internal components.

Discharging Process of Sealed Lead-Acid Batteries

When power is drawn from an SLA battery, the discharge process begins. The rate of discharge significantly affects the battery's capacity and lifespan. Understanding this process helps users optimize their battery usage for maximum longevity.

During discharge, both positive and negative plates gradually convert to lead sulfate, while the electrolyte becomes increasingly diluted. This process continues until the voltage drops below usable levels, typically around 10.5V for a 12V battery. However, it's crucial to avoid deep discharge, as this can permanently damage the battery's internal structure.

Advantages of Sealed Lead-Acid Batteries

SLA batteries offer numerous benefits that make them ideal for many applications. Their maintenance-free design eliminates the need for regular electrolyte checks or topping up. The sealed construction allows installation in any orientation, making them versatile for various mounting configurations.

These batteries also demonstrate excellent reliability in extreme temperatures and provide consistent performance under varying loads. Their relatively low cost per watt-hour and long service life make them economically attractive for many applications.

Applications of Sealed Lead-Acid Batteries

The versatility of SLA batteries has led to their widespread adoption across numerous sectors. In uninterruptible power supplies (UPS), they provide critical backup power for computers and medical equipment. Emergency lighting systems rely on their reliable performance during power outages.

Solar energy systems often employ SLA batteries for energy storage, while electric vehicles use them for starting, lighting, and ignition purposes. Their stable voltage output and ability to deliver high current make them ideal for these demanding applications.

Maintenance and Care for Sealed Lead-Acid Batteries

While SLA batteries are maintenance-free, proper care can significantly extend their lifespan. Regular voltage checks help monitor battery health, and keeping them at appropriate temperatures ensures optimal performance. Proper charging practices, including using the correct voltage and current limits, are essential for longevity.

Storage considerations are also crucial—batteries should be kept in a cool, dry environment and maintained at proper charge levels even when not in use. Think of it as keeping a car in good condition even when it's parked in the garage.

Common Issues and Troubleshooting for Sealed Lead-Acid Batteries

Despite their robust design, SLA batteries can experience issues. Common problems include sulfation (the buildup of lead sulfate crystals), internal short circuits, and capacity loss. Understanding these issues helps users identify and address problems before they become severe.

Preventive measures, such as avoiding deep discharge and maintaining proper charging protocols, can help avoid many common problems. Regular testing and monitoring allow early detection of potential issues, ensuring reliable performance throughout the battery's life.

Conclusion: Understanding the Power Within

Sealed Lead-Acid batteries represent a remarkable achievement in energy storage technology. Their reliable performance, maintenance-free operation, and versatile applications have made them an indispensable part of our modern infrastructure. By understanding how they work, we can better appreciate and utilize these powerful energy storage devices.

Whether powering emergency systems, supporting renewable energy installations, or providing reliable backup power, SLA batteries continue to prove their worth through consistent performance and dependable service. As we look to the future of energy storage, the fundamental principles and proven reliability of SLA technology will undoubtedly continue to play a crucial role in our powered world.

Explore our range of UltraMax LiFePO4 Batteries!

-

UltraMax 12V 100Ah DIN AGM Batteries for Caravans/MotorhomesSpecial Price £141.99 Regular Price £179.98

UltraMax 12V 100Ah DIN AGM Batteries for Caravans/MotorhomesSpecial Price £141.99 Regular Price £179.98

3 Item(s)